Knowledge database

Do you have some special knowledge

or a handy hint ?

Send it to

Read the Terms of Use before reading further

Directory

Hino

Rainbow - Wikipedia, the free encyclopedia

Air Cleaner Filter

Found huge differences in cost.

Repco sell Ryco HDA 5735 - cost $264.00 (10% off for RAA)

Fleetguard AF25231 - cost $68.00

Kevin

Ed - Multispares sell them for 47.95

to top

to top

Air Con Gas

Originally the RB145A buses would have been charged with 'R12' which is a hydrocarbon gas.

As part of the import process these should have been converted to 'R134a' which is still

the most common gas used in Australia.

The downside to this is that R134a will slowly leak, requiring a top up after some years.

Australian supplied buses (RB145K) would have been charged with R134a originally.

Bob Wood

to top

to top

Air Con Lab le

Sometimes there will be a label on the filter, which is inside the vented panel on the RH side behind the front wheel.

Bob Wood

to top

to top

Engine Serial Number

Read the owners manual ! Page 16

to top

to top

Air Tx valve change

When my aircon stopped working the first diagnosis found a leak on the compressor.

After having it rebuilt with all new seals it still leaked, indicating a blockage in

the system which proved to be the Tx valve. Now the Tx valve is the original component

around which Hino built the bus!

It's on the upper side of the LH end of the 'hump' aircon unit. The simple and lowest

cost solution was to cut a hole in the roof (in the right place) to enable the valve to be changed.

The alternative would have been to remove the entire aircon unit from the hump.

All now working as it should with rebuilt compressor, new Tx valve, new filter and new gas.

The cover required a little hand-beating to get the curves right and a gasket to seal it.

A couple of coats of paint now to finish it off.

Cheers Bob

to top

to top

Engine Serial Number

Read the owners manual ! Page 16

to top

to top

Vehicle Identification Number

Read the owners manual ! Page 16

to top

to top

Clutch travel

RB145a Clutch travel

I have had an ongoing issue with the clutch, too much travel resulting in unsatisfactory gear shifts.

I have rebuilt both cylinders and replaced the ball joints on the gearbox end of the shift cables but the problem remains. But now I have found it!

If you squirm in on your back under the dash so that you can move the clutch pedal with one hand and put the other on the clutch pedal pivot bearing and

move the pedal you might find a lot of play. On mine there is a spherical carbon bush held between two plates and this bush had crumbled up to almost

nothing resulting in a lot of slop and pedal travel before the cylinder moved.

Go to the bearing shop and get a basic sealed bearing with a 15mm bore and

jamb it in between the two plates and winch the two retaining bolts up. Job done for less than $20 and the clutch is great.

I did not even try and go looking for the OE part.

Regards,

Paul carter

to top

to top

Isolation switch

There are two.

One is on the right at the bottom of the dash,

a pull in / out and turn at same time;

The other inside the engine bay, on the left hand side on a panel, a

flip up / down switch. Use this when working on the engine to protect yourself.

to top

to top

V Belts

I just replaced all the V belts and have the Gates

part numbers as follows:

Vacuum pump - Gates XL9355 - 12mm x 911mm

Alternator & A/c

- 2 x Gates TR24538 - 17mm x 1380mm

Power Steering

- 2 x Gates XL7455 - 10mm x 1171mm

Total cost from

Statewide Bearings (Gates Distributor) $100.65

Best

regards Bob

to top

to top

Engine cutout (mystery solved)

Engine cut outs solved!

Our 1987 RB145 has an engine stop system using a vacuum actuator which is controlled

by a solenoid valve.

The bus has always started easily, run well and give good fuel consumption with

the one embarrassing and potentially dangerous limitation that at 2700-2800rpm

under load, the engine would suddenly cut out. It would then require a wait of

some 10 seconds or so before it could be re-started. Once re-started, performance

was completely normal.

As well as consulting with other RB145 users, engine specialists, auto-electrical

specialists, diesel specialists etc. I have spent many, many hours poring over

the manuals and circuit diagrams for this bus, trying to understand the logic

of what was happening. Testing proved that this cut-out did not occur while free

revving in neutral, which led me to study the wiring diagrams, where the only

circuit that included the neutral switch and rpm

pick-up was the warm-up program. Disconnecting the warm-up controller made no

difference so after numerous other electrical tests the engine stop solenoid

was rewired to be powered directly from the ignition switch. Again, no change.

Since there are two solenoid valves in close proximity I also checked the idle-up

solenoid in case there was some unwanted interaction. That just about ruled out

the electrics as the culprits.

I then went on to study the vacuum system, again could not find any possible

cause for what was happening. In such a generally simple engine system, we were

running out of possible villains.

Further road testing showed that by running downhill in a lower gear, the engine

would spin up to 3000rpm quite happily but then applying the accelerator caused

it to cut out immediately.

After further consultation with experts it was concluded that the problem had

to lie in the injection pump/governor. Further consultations with the fuel injection

experts agreed that the pump had to come off for a proper evaluation on the test

bench. So, the injection pump was duly delivered to the FInj. intensive care

department where it was ultimately given a clean, if expensive, bill of health.

Talking through the problem with one of their people,

he asked about the air piping leading to the turbocharger.

Back home I carried out a very detailed inspection

of the entire air system which revealed a tell-tale

imprint inside the large rubber molding that connects

directly to the turbocharger. Under high airflow conditions

while under load, this rubber molding was being sucked

flat across the air inlet to the turbocharger, cutting

off the air supply.

The molding is available ex Japan at considerable expense ($350+ in 2011) so

has now been replaced by an adaptation made from a silicon reducing elbow, a piece

of mandrel bent aluminium tube and a silicon joiner.

The molding is available ex Japan at considerable expense ($350+ in 2011) so

has now been replaced by an adaptation made from a silicon reducing elbow, a piece

of mandrel bent aluminium tube and a silicon joiner.

The result, perfect. While accelerating I can now

let the engine run up to 2900-3000 rpm without fear

of an instant cut out, and when necessary, I can keep

up with the traffic at 100kmh.

(I bet few saw that cause coming. Excellent write up Bob - Ed)

to top

to top

Steering slack / back

lash

Since I have had my Hino, I have been bothered by what

I felt was excessive backlash in the steering. By chance

I discovered that the backlash is adjustable - so I

did it. Made a world of difference to the "feel" of

the drive and controllability of the vehicle on the

highway. If anyone is experiencing similar problems

contact me and I will point you in the right direction.

Steve McDonald

That's good you have been able to improve things. Have

you visited Ron's website?

You will find it contains both workshop manual and

parts manual for the RB145 with full details of the

steering box adjustment you have done. The trap with

this type of steering box is that if all of the slack

is adjusted out in the centre, it can become stiff

at the outer ends (full lock). There is also the possibility

of play in the sliding shaft that connects the steering

wheel to the steering box. Bob Wood

to top

to top

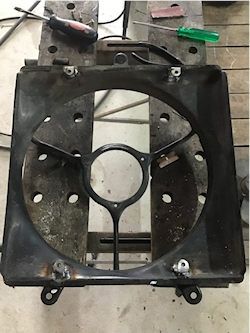

Engine mounts

Had reason to check my engine mounts and found one

had parted. Not sure they were correct parts anyway.

Solution was to fit Mackay #A2509 mounts which require

slight mod to the engine brackets, ( see

pic attached ). Also, due to the limited space

around the RB145 engine, it is necessary to loosely

fix mounts to brackets before re-fixing brackets to

engine. Then with the jack removed from under the engine,

tighten everything.

The mounts are available from most auto parts suppliers

for around $70 per pair.

One post script. After installation and settling, I

found I had to add a 5mm thick packer under each mount

to bring the crankshaft pulley bolt in line with the

hole in the cross-member. I cut them from 5mm steel

plate. 1 x 12mm hole then jigsawed down to make a slot.

Bob Wood

to top

to top

Expansion Tank

The expansion tank, it will never remain full ! As

the water in the engine heats up it expands, and it

must go somewhere. On cooling it contracts, thus the

expansion tank empties. It is ok to go down to say

half way or even less, just keep an eye on it and as

long as it does not empty, you do not have a problem.

And do not open the system more than you need to, you

let air in and this causes corrosion, or could do,

should not if you have correct additives. Also, you

have a low level light and alarm, so wait until it

goes off, if it does in short time you have a leak,

if not you do not have a problem. I do not look at

my water level - at all - until either the alarm /

light comes on or I need to change the whole systems

water.

to top

to top

Overheating - fans

Had trouble overheating going up long steep hills.

The trouble was one of the front fans wasn't working

which caused the other fan not to work.

They are 12volt fans. One won't work without the other.

Do a circuit test.

One of the brushes was sticking. Easy to fix and solved

the problem.

Brian

to top

to top

Door top guide roller

This roller will eventually wear out and may cause

the door to rattle.

No idea where to find a replacement, but it can be

made out of a nylon rod on a lathe.

Anyone got another option please

to top

to top

Brake Pedal Assembly

Removal

When I came to do this job I found the manual was somewhat

lacking. Must have been lost in the translation! Hopefully

these notes will make it easier for someone.

Brake Pedal Assembly Removal

Bob Wood

to top

to top

Auto Cooling

Auto Cooling Pty Ltd, Factory 7 / 216 Blackshaws Rd,

Altona Nth VIC. Ph. 03) 9362 7799

to top

to top

Engine shutoff fails

There are many possible reasons for the engine failing

to shut off, but a common item to wear and fail is

the engine shutoff vacuum operated switch.

It can be found on page 19 of the motors workshop manual

just to the left and above the number 27, or in this

image.

This item needs to be removed, an easy procedure, and

the two main parts separated by unbending the retaining

lugs.

Inside, the rubber diaphragm will be found to have

a split.

This can be repaired by using a rubber glue that remains

flexible, eg. a shoe repair glue, and placing a thinnish

flexible blob over the split.

Reassemble and reinstall.

This repair will survive for quite some time, and saves

you a fortune !

to top

to top

Gravel and sand roads

When traveling on gravel roads, reduce your speed and

reduce tyre pressure.

This will substantially reduce the risk of tyre failure,

and other damage from flying rocks.

On sand, reduced pressure improves traction and reduces

sinking.

Be sure to reinflate tyres when back on the seal.

to top

to top

Tyre pressures

When an RB145 bus fitted as a motorhome is fully loaded,

the gross weight will be close to 6 Tonnes.

According to tyre charts, front tyres need to be 10

ply minimum and operate at 75 psi (5.17 bar) and rear

tyres need to be 12 ply at 85 psi (5.86 bar).

(Tyre pressures depend on the make of the tyre so check

for your tyres.)

However these pressures results in a harsh ride and

increases the possibility of tyre damage.

It is recommended to have tyre pressures at; front

70 psi (4.83 bar) and rear 75psi (5.17 bar). For these

pressures, 10 ply tyres may suffice.

This also improves steering and may reduce sway if

your vehicle suffers from this.

The increase in fuel consumption is not significant.

Links here,

and here (light

trucks).

to top

to top

Springs and dampers

Hino RB145 buses converted to motorhomes are at the

maximum weight for the spring sets, and adding an extra

leaf to each spring set dramatically improves the ride,

and avoids or reduces bottoming out.

Haire

Truck & Bus Repairs Wodonga, Victoria, do an

excellent and price competitive job.

Wilkinson's

Engineering Atherton, Queensland, possibly

do the best job in the country. Not only do they add

a leaf to each spring set, but each set is removed

and individually retempered.

Powerdown is

the pioneer and leading supplier of Australian designed

shock absorbers and suspension components for trucks,

buses, 4WD's and European vans. Our shock absorbers

have been specifically designed for Australian roads

and climatic conditions. Powerdown has an extensive

distribution network throughout Australia and New Zealand.

Phone 02 4949 0000.

Front Shock absorber, RT 336. (road train)

Rear Shock absorber, RT104M3, heavy duty, non adjustable

with bushings to fit

Cost $225 per pair (2013)

Be sure to check the dampers (shock absorbers) are

working, or have them replaced.

to top

to top

Windscreens

O'brien

Glass Product # 818991

Koala

glass

to top

to top

Air Conditioner V Belts

Any one who has had to purchase V belts may have received

a shock at the price.

Well the other day the air con did not work and I thought

it had lost it's gas.

After organising an appointment at an air con fixer

place, I decided to check if the engine was still in

the housing as it has performed flawlessly for some

long time, actually since the last oil change, and

lo and behold, the air con belts were not there !

Well only the remnants remained. So being computer

savvy I decided to look on line and found the first

link to be Super Cheap Auto. Yes they had the right

size, code 11A1130M and only $19.99 for the pair !!!

Not only does the air con work better, I am a happy

and cooler man.

Ron

PS if any one purchases the belts for the alternator

or the steering pump, please pass the code onto Admin,

email at top of page - thanks.

Bob has written - see Belts - V Belts

to top

to top

Air conditioner compressor

Air conditioner compressor replacement. Sanden model

part number cxs7867, sd7h15 it is a universal type

and you will need an adapter plate.

to top

to top

Reading oil dip stick

I would like to know how to read the oil dipstick,

there are no marks showing low or full however there

appears to be a very small slot approximately 25mm

long but showing no levels, I am only guessing the

bottom of the cutout is low and the top is full but

this only a guess and that I do not like. My motor

is the W40C-T. I presume they are all similar ? Norm

Norm, You are right, that is how Hino does the oil

levels. You are also right regarding the motor, they

are all W40C's and the T is for turbo-charged. Another

way to check the oil, when you do an oil change, put

on a new filter, add exactly 11 litres, start the engine

to fill the oil ways and filter, and then stop, wait

a minute for the oil to settle and then check the oil

measuring stick, and it should be on the full mark,

or top end of the slot. All the best, and thanks for

the question, glad to be able to help. Happy travels.

While on the subject of oil, grade to use is 15W40,

and change oil and filter every 10,000 km. At the same

time, clean the air filter. Try and grease the nipples

every 5,000 km.

to top

to top

RB145 on car license

There is a person advertising an RB145A for sale on

Gumtree and also advertising that it can be driven

on a car licence. Somehow he's had it de-rated to a

GVM of 4495kgs to bypass the light rigid driving licence

requirements and also the yearly safety inspections.

Problem is, as we all know, is that you cannot get

a fitted out RB145 under 4500kgs under any circumstances,

so if some poor person buys this vehicle believing

they can, they will certainly be in trouble if the

vehicle is weighed by state transport authorities and

worse still, if they are unfortunate enough to have

an accident, their insurance may be void (refer to

Collyn Rivers latest article in the Wanderer). I would

just ask that if you know someone considering a Hino

that you please point this out to them so they don't

get caught out.

Cheers, Les

Ed comment - the tare weight of the RB145 without the

seats is 4495 kg. When fitted out, with full tanks

and ready for the road, the GVM is close to 6000

kg.

to top

to top

Hino extra radiator

The Australian assembled RB145 has an extra radiator

behind the air conditioner condenser on the right hand

side of the bus.

The imported RB145A's don't have this extra radiator

and I was wondering if any of these owners have had

any overheating issues whilst traveling Oz? I've heard

of an owner who added extra cooling for towing but

that's all. Perhaps our 'group' can shed some light

on whether their vehicles cope ok without the extra

radiator?

When I remove my small radiator I was planning on using

'blank off' rubber caps 16mm I think they are, plus

hose clamps obviously, to ensure the water flows straight

through to the front radiator and back again.

Admin - I have driven in 40 degree heat full throttle

up the steep central divide mountains in third gear

for a long time, and no overheating. The temperature

gauge will rise much hotter than normal as

per the owners manual until the electric fans

start, and right to the top of the normal zone, but

this is below the RED zone. I have heard on more than

one occasion of owners modifying cooling systems as

they believed their units were over heating, but this

is not the case.

photos from Les Trask

.jpg) .jpg)

.jpg) .jpg)

to top

to top

Bus heater system removal

Hi my Hino RB145 has a water pump in front of the left

side rear wheel which was for the heater system I think.

I have removed the heaters and would like to remove

it and the redundant pipes, as I would like to fit

a water tank there. Can anyone tell me if this possible?

Gary

Gary, the water pump and diesel heater unit you

are referring to is to heat the engine water system

for the bus in the extreme cold of Japanese winters.

It is possible to remove this system in total as well

as all the bus interior heaters along with all the

pipe work from the engine and return.

The electrics need to be disconnected beneath the floor

and the terminals protected from the environment by

sealing in a plastic bag and securely tied to the chassis.

PS On the other side of the bus is the diesel heater

unit to keep the system from freezing in the -30C temperatures

of the Japanese winters. This can also be removed.

Seal the diesel line that comes from the tank. This

line can be used to supply diesel to a diesel heater

unit to heat the bus internally to great effect.

Note: the outlet to this line is not at the bottom

of the tank, so you can not run out of fuel for the

engine, or put another way, the fuel will stop flowing

here before the tank is empty, just in case you wonder

why the heater stopped when there is still 10 or 15

litres of fuel in the tank - Ron

to top

to top

Tubeless tyres

After a lot of searching I stumbled over a useful source

of 17.5 x 6.00 tubeless rims with the correct 5 stud

centres and 127mm offset.

These allow the use of 215/75 or 205/80R17.5 tubeless

tyres and fully comply with the Hino parts manual.

For anyone interested, contact Dave or Nathan at Tyreright,

Wangara WA

Tel. 08 9302 5055 or info@wangara.tyreright.com.au.

They import them by the container load for NW mining

use and sell them at $170 each.

Cheers Bob Wood .

Admin - I asked Bob if he could

give an insight into the use of the tyres - here

is his reply.

When I bought the bus it was

sitting on 17.5 x 5.25 tubeless rims which had 115mm

offset and 8mm centre thickness. I now know these

were commonly fitted to the somewhat lighter Hino

Dutro trucks as well as Toyota Dynas. The tyres were

215/75 Yokohamas on the front and 205/80 Bridgestones

on the back and were all in very good condition.

I found it had some tendency to wander and all the

usual swaying problems.

The swaying was largely tamed by replacing the shock

absorbers at both ends - the rears are the Powerdown

specials RT104M3 - and anti-roll bar bushes. This is

the first bus I have ever driven and is the complete

opposite of my normal drive.

My research revealed that the rims were the minimum

recommended size for the 205/80s but below minimum

for the 215/75s and with little published data to work

with, I had inflated them to 70psi. It felt OK, but

I had nothing to compare with. With my tyres now fitted

to the new rims the tyre place inflated them to 90psi.

I have only driven it the 100km home since the new

wheels were fitted but it certainly rolls along a little

easier and maintains speed with a little less throttle.

That may indicate that the 70psi was too low. The wandering

also seems to be less, and to me it feels more 'planted',

although that may be wishful thinking, I'd just parted

with a chunk of unbudgeted money :-(

The

front tyres will now be sitting a little flatter, due

to the wider rim, but may take a while to settle and

wear to their new format. The track at the front is

about the same as it was. The track at the rear is

effectively increased by a few mm due in part to the

offset but also the 2mm extra in centre thickness.

The outside edge of the rim is just about flush with

the body side. There are no conflict problems on the

inside. The

front tyres will now be sitting a little flatter, due

to the wider rim, but may take a while to settle and

wear to their new format. The track at the front is

about the same as it was. The track at the rear is

effectively increased by a few mm due in part to the

offset but also the 2mm extra in centre thickness.

The outside edge of the rim is just about flush with

the body side. There are no conflict problems on the

inside.

Overall

then the footprint is marginally wider but the tyres

are much better supported, lessening the tendency for

the tyre to flex sideways relative to the wheel. Overall

then the footprint is marginally wider but the tyres

are much better supported, lessening the tendency for

the tyre to flex sideways relative to the wheel.

On my limited experience I am pleased with the result.

Of course, I already had the tubeless tyres so my cost

was to replace 6 rims and to buy a complete spare rim & tyre

as my spare had been a 16". Compared with the original

spec 7.00R16 on a split rim, the overall rolling diameter

is effectively the same but the tubeless tyre will

run cooler. I shall be carrying a repair plug kit which

hopefully would allow me to repair a flat without removing

the wheel - time will tell.

Having spoken with many arms of the wheel and tyre

industry over the last few weeks, it is nice to be

able to prove wrong those eminent gentlemen who assured

me that "you won't get any", "they don't make them",

they wouldn't be allowed", "you'll need all new tyres

as well" etc. etc. I'm sure you've also encountered

some of these 'experts'.

The responses I got when I asked for feedback showed

that many are running 7.00R16s while some have opted

for 7.50R16s. Nobody else had gone tubeless but that

choice had already been taken by the previous owner

of my bus.

Interestingly, the operator of a local school bus contractor

runs all of his smaller buses on 215/75s and swears

by them.

The other gem was that in the Bridgestone range, 205/80s

are $300 each, 215/75s are $430 each.

to top

to top

Swing away spare tyre

carrier

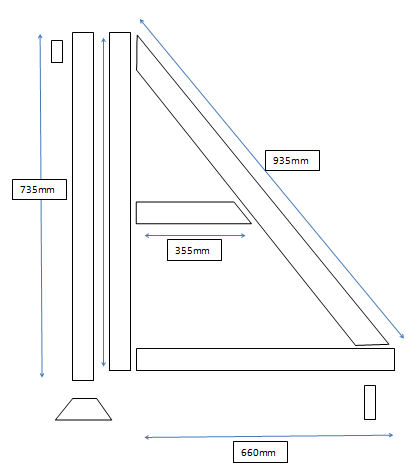

List of components 1 - 50*50*1.5 Square 735mm

1 - 50*50*1.5 - 725mm

1 - 50*50*1.5 - 660mm

1 - 50*50*1.5 - 935mm

1 - 50*50*1.5 - 355mm

1 - 40*40*3 angle - 70mm - external top mount

1 - 65*65*5 angle - 150mm - main bottom mount

1 - 30*5 flat - 60mm - anti luce tab

1 - 60*3 flat - 100mm - internal mount for top bracket

2 - nylon bushed hinges

1 - Anti Luce Lock

3 - 100*25mm bolts cut to suit

3 - nuts to suit bolts

4 nuts and bolts to mount the carrier to the bumper

and the top mount 12mm diameter and about 30mm long

I bought the hinges and anti luce lock from OVESCO

and the heavy bolts from a local bolt specialist.

The anti luce lock should be available from any trailer

parts place. (This is a common device on trailer tailgates).

Bill Behan

to top

to top

Swivel front seats ?

Has anyone got drawings or other information regarding

swivel seats for the front ? Bob

Important stuff to know DO

NOT bolt anything to the floor until you have

located the seat to your preferred driving position

and you are sure it will rotate properly without hitting

anything.

To start with, use the original mounting holes. The

engineers like this a lot.

If you can't utilise the holes at least use the

original brackets, this too is really good. But make

sure you fill the holes to stop water etc. getting

in.

Use 8mm high tensile bolts and nylock nuts.

Use 3mm plate to make the new mounts.

Check out Vehicle Standards Bulletins - used to be

called DOTARS -for everything related to engineering

in motor vehicles, trailers, etc. ( link

here).

I used Subaru seats because they had a arm rest but

the seat was too long and hit my calf all the time,

they also had a pressed metal base and formed foam

which tended to get uncomfortable after a while. So

I changed to Hilux seats. These are a lot (50mm) shorter

in the seat and have springs under the foam to give

a nicer ride, they are also a smallish seat (as opposed

to something out of a commodore).

When you find a seat simply cut the old pressed metal

mounts off and bolt the runners directly to the new

mounts you make.

Drivers side floor to rotating seat base

2

* 370mm long 3mm plate bent to 50mm * 30mm. Note that

the bracket is over bent to suit the rotating base.

This is the rear bracket. The 50mm edge is bolted to

the floor utilising the original under-floor reinforcing

brackets. The front is exactly the same. It's all mounted

inside the frame of the rotating base. 2

* 370mm long 3mm plate bent to 50mm * 30mm. Note that

the bracket is over bent to suit the rotating base.

This is the rear bracket. The 50mm edge is bolted to

the floor utilising the original under-floor reinforcing

brackets. The front is exactly the same. It's all mounted

inside the frame of the rotating base.

Bolt the bent bracket to the rotating base.

Rotating base to seat brackets.

This bit is going to depend entirely on the type of seat

you end up buying. I have used Toyota Hi Lux seats

because they are relatively small and they have inner

springs to help with the comfort factor.

This bit is going to depend entirely on the type of seat

you end up buying. I have used Toyota Hi Lux seats

because they are relatively small and they have inner

springs to help with the comfort factor.

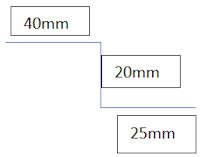

2 * 370 long *85 wide 3mm plate bent to a Z section.

Remember you need left and right brackets. The 40mm

and the 25mm are to make up for the difference in width

between the rotating base and the seat. The 20mm

is for height adjustment depending on how tall you

are. This is the right hand side bracket. In this photo

I have used a nut as a spacer to allow the slide to

run free.

Car

seats are usually built so the driver is leaning backward

a bit with the legs extended out in front. In this

photo I have used a piece of tube at the rear to bring

the seat up to more level so I can sit more upright.

Again this is entirely adjustable to preference. Car

seats are usually built so the driver is leaning backward

a bit with the legs extended out in front. In this

photo I have used a piece of tube at the rear to bring

the seat up to more level so I can sit more upright.

Again this is entirely adjustable to preference.

When you have everything bolted together you can start

playing with where you want the seat to be located.

In cars the relationship between the steering wheel,

the pedals and the seat never line up. It might feel

good but if you get a tape measure out you'll be surprised

at how far out of alignment they really are. So when

you are playing with seat positioning don't be too

surprised to find that the seat may not be exactly

parallel with the side of the bus. I moved my seat

inboard a bit to allow it to rotate properly and then

turned it a bit (about 10mm off square) so my feet

lined up with the pedals. This also had the benefit

of giving me a bit of elbow room.

Passenger side

2 * 420mm long 3mm plate bent to 50mm * 30mm . The

passenger side is much the same as the driver side

except for the narrower mud guard. Which means the

seat is going to hang (unsupported) over the edge.

I welded a small bracket to the overhang and then bolted

the bracket onto the mudguard.

How much overhang you have is going to depend on how

much room you need to rotate the seat.

In this photo you can see how the overhang ends about

60mm past the mudguard and in line with the bottom

edge of the guard. I have also moved the seat belt

mount.

On another RB 145 I worked on, I extended the mudguard

out to level with the width of the seat which looked

really nice. But the seat belt mount was a lot of mucking

around fixing it to the floor frame and the narrower

walkway made things a bit tight.

With the passenger seat I got a bit fancy and made

the base to seat bracket on a taper to pick the back

edge up a bit. This is 50mm at the rear and 20mm at

the front. In this photo you can see the seat on the

tapered bracket bolted to the base. And the base bolted

to the mudguard bracket with the overhang nicely supported.

DOTARS has all the specifications on seat belt mounts

so double check everything. I used 3mm plate 60mm *

120mm.

The nut is welded to the backing plate and the backing

plate is riveted into position so it doesn't move when

you tighten the bolt. This photo of the passenger side

shows the seat belt mount and one of the plates that

support the overhang brackets inside. Note the rounded

corners on everything and it's all painted to prevent

rust and look a bit professional.

The gear shift

When moving the drivers seat

you will probably find that the gear shift fouls

somewhere. An easy fix is to cut it and move it sideways.

I've been told this is a common 'fix' when converting

(expensive) cars from left hand to right hand drive.

Bill

to top

to top

Air Con woes

I had a problem with the air con compressor and the

thing froze up.

The first time this happened it shredded the drive

belts, so thinking that there was a bit of slippage

I did the belts up a bit tighter.

Then it happened again tore the rubber out of the clutch.

You can't buy these bits.

I have found a local company who can vulcanise the

rubber back into the air con clutch.

I had to make a jig to hold both the inner and outer

bits in perfect alignment but it works. The cost was

a few dollars to buy the steel for the jig and a carton

of beer for the vulcanising.

So if you have a problem with the air con clutch it

can be repaired.

Now I have to find out why the compressor is freezing

up, but I think the fans are not working.

The company I found to repair my air con clutch is

called WEARX at Hexham, not far from Newcastle. http://www.wearx.com.

They do not repair air con clutches but they do vulcanise

rubber so they said they would do it for me if I made

the jig to hold the two pieces in perfect central alignment.

Put that info onto your resources page for future reference.

Bill

An update to my earlier air con problems. It turns

out that the reason for the unit 'freezing' up was

actually the magnetic clutch bearing. Mike Varley from

Mt Isa (on our list) pointed me in the right direction.

The bearing is a massive 2 race unit and literally

half the bearings were missing. This was causing the

pulley to stop turning and thus destroying the drive

belts.

It could sit and idle all day and the pressures were

all correct which was why all the air con specialists

I went to could not find anything wrong with it and

suggested that the air con pump had a problem. Not

one of these specialists suggested looking at the clutch

bearing.

to top

to top

Wheel Winder Part Required

Does anyone know where I could procure the eccentric

spindle that winds up the chain to lift the spare wheel

? Ron

Something off a another model should fit. May require

slight modification but a sample or a picture to compare

would be req'd. cost would be $75 inc gst

After contacting many wreckers around the country I

had no luck.

On a recent visit to NZ, I looked on line and talked

to a couple of truck wreckers.

As I drove around I visited one in Taranaki, just north

of New Plymouth, and he also did not have one, but

suggested I try one off an old Mitsubishi truck. I

took the whole unit back to base by Qantas hoping the

spindle would fit, as it looked by eye to be good,

but on removing the old unit found the second hand

Mitsy unit is identical and fitted exactly. Looks like

the Chinese are not the only ones to use parts universally

between companies.

So contact Peter above and he will send you a part

that fits.

Ron

to top

to top

Brass Slippers for Springs

I have just replaced the brass slipper plates in the

springs on my bus. To do this I had to make a little

jig to put the locating dimple in the plate (this just

holds it in place in the spring).

The front springs have to come out to fit the plates

(it's not that hard a job and if you need bushes you

may as well do it while you are there). I haven't fitted

the rear yet but I think it can be done in place by

spreading the leaves.

If any one is feeling keen and you want to do this

I could make them for you. One metre of brass costs

about $50.00 plus delivery and and I need to pay for

the use of oxy to heat it up enough to work it to shape.

I reckon I could make a set for $100.00 plus delivery

to you.

By comparison Hino tell me there are none in Australia

and wanted $68.00 for each slipper plate. There's 16

of them.

Bill

to top

to top

Wreckers

It seems difficult to find wreckers for our Hino buses,

and not just in this country.

This maybe as a result of the great reliability of

our machines.

So in summary this is what I have found -

Firstly look at the links

page for possible places.

Secondly, any wrecker for small to medium Japanese

trucks should be tried, as often parts for other makes

of Japanese trucks are interchangeable with Hino, for

example Mitsubishi, Nissan, etc.

And thirdly, spend a bit of time and read all the other

knowledge based information, it is surprising the little

hints that are imbedded in these gems of wisdom, and

just maybe the answer that alludes you.

Happy hunting..

Ron

to top

to top

Rust - Roof Line

Has anyone had experience with rust in the roof at

the front?

This appears to be a common problem with the RB 145's.

I have had a fellow suggest that the problem occurs

because the air conditioner encourages moisture to

form in that area and that is why the newer models

have vents in the roof, to get rid of the moisture

laden air.

So I am wondering if anyone has heard that explanation?

The other possible cause is moisture being sucked up

(via a vacuum effect) through the rear frame work.

I know from experience that dust and exhaust fumes

enter the bus via the rear column.

When I built the bus I was really amazed to find carbon

soot in the insulation material at least a third of

the way forward from the rear and fine dust in cavities

even further towards the front.

So am absolutely convinced that moisture laden air

gets into the area between the outer skin and the the

plastic air con liner where it condenses and sits on

the frame work and encourages rust to form.

I have made several little repairs to that area but

I realised the problem was never going away. I ended

up removing the entire curved bit (I call it a 'hip').

Well not all of it, but a length of 2.4 metres from

the front joint .

I wasn't too surprised to find the rust had gotten

into the frame members, and that is where the trap

really exists. Everyone is probably repairing the visible

rust and not realising the rust is eating the frame

of the bus away.

I am interested in your thoughts on this issue and

if anyone is keen I could do a little 'how to' on replacing

the roof hip utilising the photos I took.

Bill

Yes I too have had rust problems in the roof area,

just above the guttering, and yes it is from condensation

which I have been told is common in the RB145's.

My thoughts are - it is caused by the cold air from

the air-con going along the roof line inside, where

the air comes out into the bus. This cold air would

cause condensation along the whole length of the bus,

the more and longer you use the air-con the more likely

you are to get moisture there, and if then you switch

off and park the bus, this moisture will eventually

cause problems.

The thing that could be done to get rid of this moisture

is to leave the fan for the air-con running for sometime

on high without the air-con going, before you put the

bus to sleep. My guess is that you would need to get

the bus warm again and run the fan for at least fifteen

minutes.

Keep the engine running otherwise the battery will

be discharged and bus batteries should always remain

fully charged to ensure long life.

I took my bus to a panel shop and had the rust cut

out and replaced with steel. I think a fibre glass

fix up job is probably a waste of time.

And yes, make sure the panel shop does check for any

structural damage.

Ron

Thanks for this.

In my bus, there is a strip (~300mm wide) of 0.9mm

opaque plastic sheeting, pushed into place between

the wall and roof rails and sealed with silicone

all the way along. This formed a smooth, curved

rear for the A/C duct.

The silicone completely covered the steel rails and

with a gap of ~20mm between the plastic and the steel 'hip' panel,

the condensation problem would have been solved.

Not sure if this was standard on all 145's but it may

also explain why there's no rust in that area. Again

ambient relative humidity helps. Cheers Bob

Hi everybody . from northern

NSW, we have had our 145a now for 10 years now we

never use the AC as I removed the motor drive belt

to it 8 years ago the vehicle is always enclosed

in a shed and now rust has broken through above the

drivers door the 145a has had little use the last

2 years as we have been having other adventures.

Food for thought? Sue

Hello Sue, The bus will have

been used before you owned it and the air-con used,

and the process of rust development will have started.

Once rust begins, it continues relentlessly using

any atmospheric moisture until its presence is shown,

nothing stops it except complete removal, so inside

storage may slow the progression but it will not

stop it. Sorry for the bad news, but you have to

live with the problem and in time it will show in

other places. Kind regards, Ron

Dear Ronald Thank you so much

for your response it was very informative. I did

eventually get the downloads off the site and they

are most helpful. My dad, Allan, also managed to

get the part he was seeking. What a great site you

have and so very helpful. You are to be credited

for the effort you have put into it. Thanking you

kindly Yours sincerely Deborah Khan and her father

Allan Coleman.

to top

to top

Refrigerator fire

Hello everyone Bad news.

I have just experienced a fire

at the rear of the Dometic 3 way fridge.

Fortunately the damage was limited to the fridge insulation,

the timber cabinet enclosure and the roof vents are

melted.

I

was lucky to be next to the bus when someone came

and brought my attention to the smoke coming out

of the roof vent. The fire was caused when the cooling

system on the fridge started leaking at the base

of the flue, this leak released the ammonia and nitrogen

mix and when I turned the fridge to GAS and lit the

pilot light the pilot ignited the nitrogen ammonia

mix. What actually caused the vast majority of the

damage was the fact that the timber cabinetry surrounding

the fridge caught fire. So even after I turned off

the LPG to the fridge the timber kept burning. I

was lucky to be next to the bus when someone came

and brought my attention to the smoke coming out

of the roof vent. The fire was caused when the cooling

system on the fridge started leaking at the base

of the flue, this leak released the ammonia and nitrogen

mix and when I turned the fridge to GAS and lit the

pilot light the pilot ignited the nitrogen ammonia

mix. What actually caused the vast majority of the

damage was the fact that the timber cabinetry surrounding

the fridge caught fire. So even after I turned off

the LPG to the fridge the timber kept burning.

What have I learned from this

experience?

If you smell ammonia it is not the toilet or cleaning

fluid, it is the fridge leaking, my eyes started to

water and I still didn't realise what it was. How slow

can I be?

If the fire alarm goes off, it does so for a reason

and it needs to be investigated. I couldn't see or

smell any smoke and I thought it was a nearby smoker

combining with the fumes I thought were coming from

cleaning fluid.

The insulation foam in the refrigerator

will not support fire, if you take the fire away

the foam will not burn.

The cooling unit of the fridge

is remarkably fragile. The unit is tack welded to

a frame and these little tacks crack due to vibration

and allow the entire weight of the cooling unit to

hang on the boiler, that's the bit at the bottom

of the flue where everything joins up.

What

am I doing next. I am going to line the fridge enclosure

with a sheet of sign white. This is a metal sheet

used in the signage industry and is only about half

a millimetre thick so it doesn't weigh much. In the

event that I have another fire the sign white will

stop the timber cabinet from catching fire and this

will dramatically lower the risk of major damage

or a complete wipe out. It will also make the enclosure

look a whole lot smarter with a nice smooth white

finish. Repairing the fridge insulation is remarkably

easy and I am taking photos as I go, for future reference.

I have also found a video of how to remove the cooling

unit from the fridge. Again this is extremely easy. What

am I doing next. I am going to line the fridge enclosure

with a sheet of sign white. This is a metal sheet

used in the signage industry and is only about half

a millimetre thick so it doesn't weigh much. In the

event that I have another fire the sign white will

stop the timber cabinet from catching fire and this

will dramatically lower the risk of major damage

or a complete wipe out. It will also make the enclosure

look a whole lot smarter with a nice smooth white

finish. Repairing the fridge insulation is remarkably

easy and I am taking photos as I go, for future reference.

I have also found a video of how to remove the cooling

unit from the fridge. Again this is extremely easy.

Repairs I have taken the cooling

unit out of the fridge and a new one is being made.

This is done by Alternate Gas Refrigeration in Arndell

Park in Sydney. This is the only company in NSW that

does this type of repair and all caravan shops and

fridge technicians send fridges here for repair.

I'm just cutting out the middleman.

I have cut out the fire damaged

urethane insulation and replaced this with a similar

product. The silver sisilation is there to reflect

heat and also prevent any damage to the very soft

urethane. I can't get a small quantity of the heavy

paper based stuff as original so I am using something

lighter but it will work.

Why not just get a new fridge?

There's nothing wrong with what I have, if you ignore

the fire damage and the fact that it no longer cools

anything. A new fridge is $3,000.00 and I have been

told they are being made in China and the quality

is not there.

The company in Sydney do these

repairs for a living and I am confident that it will

be better than a new unit. The replacement cooling

unit is about $1,000.00, so I should be able to replace,

repair and mend all the bits for well under $1,300.00.

It gives me something to do and I have learned a

whole lot of new things.

My recommendations. Take your

fridge out and have a look at the little tack welds

to see if they are broken. This is important because

it happens a lot more than we are told. Some fridge

units are delivered with tacks missing or barely

there.

Secondly and most importantly,

line your fridge enclosure with something that will

not catch fire and make a little gas fire into a

major inferno.

Taking the fridge out is also

quite easy, there are only four screws at the base

and 2 at the top and it simply slides out.

Bill

The fridge repairs are going

well and I thought I would share these links in case

anyone gets really keen about fridge modifications.

The cooling unit simply pops

out of the back of the foam box. http://www.dreampod.net/index.html shows

how to put a heat extraction fan and thermostat on

the outside of the fridge and a circulating fan inside

the fridge to help keep the air moving and reduce

ice build up on the fins.

http://rvrefrigeration.com/training-videos/ an

excellent range of videos designed to train people

on all aspects of gas fridge operation.

Don't

ever be afraid to pull the fridge apart, it is simply

a foam box which is covered in insulation material

with a plastic liner which is only 0.5mm thick. Don't

ever be afraid to pull the fridge apart, it is simply

a foam box which is covered in insulation material

with a plastic liner which is only 0.5mm thick.

I have also attached some photos

of the repairs I did a few years ago when the tack

welds broke off or the cooling fins broke. I don't

really recommend this type of repair, but it did

the job.

Please

note that the wrap around bracket on the top right

corner was not too good because it still allowed

the tube to move up and down. The point is that the

tiny little tacks that hold the cooling unit to the

frame often break and it is probably worthwhile checking. Please

note that the wrap around bracket on the top right

corner was not too good because it still allowed

the tube to move up and down. The point is that the

tiny little tacks that hold the cooling unit to the

frame often break and it is probably worthwhile checking.

Bill !

to top

to top

Insurance

Question - I've been looking for insurance but can't

get much sense out of them when they hear it's a converted

bus.

Answer - If you join the CMCA www.cmca.net.au then

as a member you can get insurance from Ken Tame, this

is not necessarily the cheapest, but most definitely

the best, check it out.

I have been a member for the last six + years and had

to claim twice, windscreen and accident, never a question.

Mine as you know is a converted bus, all RB's are of

course. It's the norm, not the exception.

Ken Tame and Associates.

t: 03 9853 5555

f: 03 9853 5554

e:

w: www.kentame.com.au

POB 2390 Kew VIC 3101

to top

to top

Sway Bars

Bill wrote - There is a difference between the Australian

RB145K and Grey import RB145A anti sway bars.

The K model has a 40 mm anti sway bar and the A has

a 34 mm anti sway bar.

If you have a problem with swaying in your model A

bus, it maybe worth infesting in upgrading to a 40

mm sway bar.

I had my 40mm rear sway bar made by Signature Sway

bars at Nowra for about $600.00.

I had to send him the original to copy and it took

about 3 weeks, but he makes the bar at Nowra and then

sends it to Adelaide for heat treatment.

New sway bar mounts and bushes. I went to a truck wrecker

and found a 40mm truck Sway bar. I then cut the mounts

off the truck unit and fitted them in place of the

existing Hino units. I think that cost about $50.00.

(Yes there was a bit of cutting and welding involved).

Signature Sway bars can make some mounts for you if

need them to.

Swaying Hino Rainbow RB145R Fellow

Hino Drivers,

I built our Hino about 7 years ago, have only traveled

30.000km since complete. I posted a blog about 5 years

ago in CMCA forum to help Hino owners solve the Swaying

problems with this imported vehicle.

I got together with the engineer for Bents Engineering

who copied my old bar (34mm) and made a (42mm) bar.

This worked a treat. No other modifications were made

to the bus, Shocks & springs all original. Bents

have informed me they have built 20 bars since, all

with positive feedback.

Bents also supply 42mm poly bushes to suit the bar.

So before you spend a lot of money on new springs & shocks,

try fitting a new bar. It will work.

Regards Bob & Di.

I bought an imported RB145 around

five years ago and experienced the swaying issue.

We put new adjustable shockers on but this did not

resolve the sway. Doug

That bar will fix the sway,

but inevitably changes the way the bus handles in

an emergency swerve situation.

See my Tech Notes in March 2013 issue re just how and

why.

Collyn Rivers

Ed's Note : Ron's Rb145A has

40 mm front, 34.5 mm rear sway bars - never had sway

problem.

to top

to top

Sway / Roll Solution

This is a dissertation subitted by Paul Carter, new information here, thank you Paul, we are all much indebted to you.

Paul Carter

(Sandy's Partner)

My Hino rolled very badly when I first purchased it so I have done quite a lot to reduce it, including.

Adjust the steering box.

New Wheel bearings (did the brakes while I was in there)

Fitted vortex generator to the rear

Played around with tire pressures.

I have it to the place where it is good to drive. Cross winds or another heavy vehicle coming the other way are just not an issue. But there are still traces of the issue still there.

I have read a bit about the orientation of the rear springs and have been giving that a lot of thought but until now could not get up enough courage to do it. The final nudge came when I read an article on another platform from someone in Christchurch who had modified his own bus and has gone on to do several others. The brief, but very informative document.

To summarize, in most leaf spring setups the swing shackle is at the rear on both front and rear axles, this means that when the spring compresses both axles moves back slightly but stay aligned. In the rear engine Hino's the rear spring set is in the other way around with the swing shackle at the front so when both spring sets compress when the bus rolls to one side on an uneven surface the front and rear axles move together just like the steering on a skateboard and thus the roll problem.

Got the first side done and all buttoned up now starting on the other side. I had to purchase a torque multiplier off ebay to get the spring bolts undone. They are crazy tight. Am replacing the bushes in the fixed spring end as they are a bit loose. Also fitting new U bolts as these are stretch to torque and as such one time use. Got them made to measure by archer springs, the price was reasonable and 24 hour turnaround.

Second side done. Went for COF this morning and drove over every bit of uneven surface I could find. Nothing, not a hint of it's former behavior. I can 100% vouch for this as a complete remedy. There are a few things I would add to the document.

1/ Fit new U bolts. ($130)

2/ If yours is the earlier version like mine the nuts holding in the front (shackle end) are not captive inside the chassis rail and will turn on you once you can get them to turn. just cut the heads off and fit new bolts,(only if they are not captive) minimum grade 8 (not 8.8) and push the bolts through from the inside of the chassis rail because you will be there till hell freezes over trying to get a socket inside there to do them up if you put them in from the outside. The back are captive but are also very tight. Get you hands on a torque multiplier.

3/ I replaced the fixed end spring eye bushes, why not while the spring is out laying on the ground. ($80)

To summarize my reading on the problem, in most leaf spring setups the swing shackle is at the rear on both front and rear axles, this means that when the spring compresses both axles moves back slightly but stay aligned. In the rear engine Hino's the rear spring set is in the other way around with the swing shackle at the front so when both spring sets compress when the bus rolls to one side on an uneven surface the front and rear axles move together just like the steering on a skateboard and thus the roll problem.

Below is the text I came across on line.

Subject: RE: Hino roll,

Hi Matt, I have now altered 6 of these narrow body Hinos, including 1 that I had and a mates which rolled quiet badly. And yes, we went through all the remedies on Facebook, magazines etc ( New tyres, stiffer springs, new Shocks, wheel alignment) but nothing worked, and generally aggravated the problem.

If you are handy mechanically this will save a lot of money. If you look at the makeup of the suspension on rear engine Hinos, 7, 8, & 9 metre, you will see that the shackles are on the rear of the front springs, but are on the front of the rear springs. So, when you drive over uneven surfaces the 2 axles are ether pulling together or spreading apart causing the rolling motion.

The cure, move the swinging shackle to the rear of the spring by turning it 180' or end for end.

Jack up your bus and block up the towbar or rear of chassis away from the springs so the wheels are clear of the ground. Remove both sets of rear wheels, remove the sway bar links and push sway bar up out of the way, undo lower shock absorber mount and push away. drop one end of the drive shaft.

Put an extended jack under 1 side of the diff housing, and undo the U bolts, lower the diff slightly to clear the spring. Undo the shackle pins from the chassis ( on early Hinos there was a nut inside chassis, later ones had a lock plate on outside) remove the spring, loosen the centre bolt and turn the leaf for the sway bar around. Refit the spring with the shackles now at the rear.

On reassembly insure the driveshaft still has at least 5 to10mm of clearance when fully closed, if not pull apart and cut a small amount off the spline as this process shifts the diff rearward aprox. 10 to 15mm.

It is critical that the pinion angle and rear gearbox flange angle are as close as possible to stop drive line growl. We just used a simple inclinometer app off our cell phone.

To line up the drive shaft properly you will need to obtain a pair of wedges, on our first bus we got some wedges from our local truck wheel alignment guys, but we then had them made by WEDGETEK engineering, 34 Klondike drive Hornby , Christchurch. Phone ( 04 ) 3499931. Cell. 021-383779 these wedges by memory are 5 deg and were about $35.00 pair plus freight, you will need to let them know the size and centre bolt hole size. The wedges are 175mm long by 60mm wide with a 22mm hole for the centre bolt and are "5 degrees" .

You just need to reassemble and repeat on the opposite side.

Believe me this is the only cure for Hino handling. It is a personal choice whether you have an extra leaf in the front springs or not. If your suspension is standard now, I would turn the springs first. Not sure what shock absorbers you have but adjustable POWERDOWN shocks set on firm work very well, also check to see if your sway bar bushes are in good order

You will not believe the difference to the ride and handling this work makes. I ran my front tyres at 65psi and the rears at 75psi, on 650x16 tyres, which makes for quiet and soft ride.

to top to top

Door Conversion

Conversion of Hino RB145 entry door from sliding to

hinged.

This conversion was decided

upon to improve the overall access to the bus, without

the effort required and the associated noise which

was a part of the original sliding door.

My door was suffering problems

which included worn runners on deformed brackets

and cracks in the inner door pressing, above and

below the middle runner port and next to the lock

mounting.

As a part of the conversion,

I strengthened the door inner skin by welding both

the cracks and a sheet metal patch into the middle

runner port, using a wooden jig to keep the door

the correct shape. It will be noticed that the door

is not straight. The lower half is slightly curved

while the upper half is canted inwards. This dictates

that the hinges must be fitted between the upper

and lower body grooves, in order to keep the two

hinge-pins perfectly in line and allow free movement

of the door.

Tools required:

1 Various hand tools, files, hacksaw etc.

2 Metric spanners or sockets 12mm, 14mm, Phillips #2

screwdriver

3 Power drill and suitable bits 3,5,8.5 & (13.5mm)

diameter. This diameter will depend on the rivnuts

selected.

4 Rivnut setting tool

5 Welding and sheet metal facilities (or a friendly

panel beater)

6 Multi-tool with steel blade / angle grinder / reciprocating

saw/cold chisel etc.

7 Anything else

The required components are

as follows:

1 2 off Heavy duty over-seal type hinges (obtainable

from Dunn & Watson, IRS, UES or others)

2 2 off Aluminium spacers 2mm thick (See sketch and

pics below)

3 2 off Aluminium spacers 3mm thick ( " " )

4 2 off Reinforcing brackets to fit hinge mountings

inside door ( " " )

5 1 off Reinforcing bracket for new lock mounting inside

door ( " " )

6 8 off M8 Steel long rivnuts, large flange

7 4 off M5 x 12mm pan head screws and nyloc nuts

8 5 off M8 x 30 button head high-tensile cap screws

9 6 off M8 x 20 button head stainless steel cap screws

10 6 off M8 Nyloc nuts

11 12 off M6 Steel rivnuts

12 1 off Outside door handle to suit (Eberhard 4-21100-K

or similar)

13 1 off Inside door handle to suit

14 1 off Lock unit (Eberhard 1-400-L or similar)

15 1off Lock striker pin (Eberhard ....... or similar - to

suit lock)

16 1 off Striker pin mount (See sketch and pics below)

17 12 off M6 x 25 High tensile set screws

Method Preparation:

1 The door auto-operator can be removed from under

the bus.

2 The door control unit, just inside the door on the

right and its dashboard mounted switch can be removed.

3 Remove the door trim panel (may be re-used in original

or modified form)

4 Remove the glued-on sealing rubbers from both the

body and the front edge of the door.(may be re-used

if in good condition)

5 Remove the lock striker pin.

Hinge installation

1 For setting the hinges in the correct locations,

leave the door mounted on its sliding runners at

this stage.

2 The hinges used in this conversion are heavy-duty,

stainless steel 'over-seal' type. It is advisable to

modify the body tab of the upper hinge to enable three

fixing bolts to be used instead of two. It is the upper

hinge that will be in tension due to the weight of

the door. Offsetting the third hole achieves a triangular

footprint for a completely rigid mounting. As in the

pic below, an additional piece of 4.5mm stainless steel

was welded to the original hinge tab to allow the third

hole to be offset.

3 In order that the outside of the door finishes level

with the outside of the body, it is necessary to measure

your hinge offset. Place the hinge flat on a level

surface and measure the height of the centre of the

pin above the surface. This is the measurement that

the hinge pin must lie outside of the body face.

4 The location of the hinges was chosen to maximise

the distance between them.

It was decided to mount the body tabs to the rear face

of the 'B' post. To ensure that the hinges are mounted

perfectly in line, it is best to bolt them to a suitable

piece of steel bar or angle by their door tabs. This

allows the hinges to be set square to the piece of

steel, and the two hinge pins kept in line while they

were offered up to the body to mark the fixing positions.

5 Examination of the mounting face shows that where

the nearside body panel and the front edge of the door

opening panel come together on the 'B' post, the surface

is not level. To achieve a level mounting for the hinge

tab, a 2mm thick spacer was made from aluminium sheet,

with its innermost edge filed to achieve a fit against

the raised surface. (See pics below)

6 Large-flanged, steel, M8 long rivnuts were fitted

through the 2mm spacer into the 'B' post. Mine required

a 13.5mm hole diameter, but do check what your chosen

rivnuts require. At this point the total metal thickness

is comprised of the 2mm spacer, the body skin and the 'B' post.

This total ~5mm requires the use of long-series rivnuts.

7 To allow the 3mm thick aluminium spacer to fit between

the hinge tab and the rivnuts, it was necessary to

counter-bore the rear face by about 1mm to clear the

rivnut flanges. I did this using a router bit in the

pillar drill with everything clamped firmly in place!!

8

With the upper hinge secured by two M8 screws, the

third hole can be drilled as a pilot hole through the

hinge into the 'B' post. After removing the hinge and

3mm packer, this hole will then require to be drilled

out to suit your rivnut which can then be fitted. The

third hole in the packer will also need to be counter-bored. 8

With the upper hinge secured by two M8 screws, the

third hole can be drilled as a pilot hole through the

hinge into the 'B' post. After removing the hinge and

3mm packer, this hole will then require to be drilled

out to suit your rivnut which can then be fitted. The

third hole in the packer will also need to be counter-bored.

9 The lower hinge position does not allow a third fixing

but the original door alignment fitting should be removed.

10 With both hinges fitted to the body, the door can

be slid into its normal closed position. The door tab

of the upper hinge is then swung onto the door, allowing

the hole positions to be marked on the door.

At

this point it should be noted that if the hinge pins

are perfectly aligned, the tab will not sit perfectly

flat on the door. The tab can be twisted slightly when

off the bus by mounting the entire length of the hinge

pin in a vice, while applying a twisting force in the

required direction to the tab. At

this point it should be noted that if the hinge pins

are perfectly aligned, the tab will not sit perfectly

flat on the door. The tab can be twisted slightly when

off the bus by mounting the entire length of the hinge

pin in a vice, while applying a twisting force in the

required direction to the tab.

11 Once the necessary adjustments have been made, the

upper hinge can be secured to the body and the three

fixing bolts tightened

12

The first hole in the door skin can now be drilled.

I drilled through one of the marked positions at 3mm

diameter with the reinforcing bracket (see pic below)

held inside the door. This marked the bracket, allowing

me then to remove it and then drill both the bracket

and the door at 5mm diameter. 12

The first hole in the door skin can now be drilled.

I drilled through one of the marked positions at 3mm

diameter with the reinforcing bracket (see pic below)

held inside the door. This marked the bracket, allowing

me then to remove it and then drill both the bracket

and the door at 5mm diameter.

13 The hole in the reinforcing bracket was then filed

out to create a slot <5mm rearwards. The bracket

is then replaced inside the door, pushed fully forward

and secured by one M4 screw & nut.

14 The holes for the two M5 front fixing screws were

then drilled through the front edge of the door and

the bracket. Note that these screws should be positioned

inwards of the rubber door seal. With these two screws

in place and tightened, the reinforcing bracket is

drawn fully against the front edge of the door and

firmly held in place.

15 The first hole in the door skin and bracket, previously

drilled at 5mm, can now be increased to 8.5mm diameter

by drilling through the hinge tab to ensure alignment,

using light pressure, so as to not distort the bracket.

16 At this stage an assistant will be useful! With

one of you inside the bus and the door closed, the

hinge tab can now be temporarily secured to the door

by an M8 screw and nut. The remaining two fixing holes

can then be drilled through the hinge tab, door and

bracket at 8.5mm and two more temporary screws fitted.

17 With some support under the rear/bottom of the door

(I used a trolley jack), one of you inside the bus

and the door closed, the two bolts securing the middle

door runner can be removed from the inside (12mm socket).

This will allow the middle runner to be withdrawn rearwards

along its track, leaving the door supported at the

front by the lower runner and at the rear by your support,

with the top of the door kept inwards by the top runner.

18 Careful adjustment of the height of your door support

will allow the gap between the front edge of the door

and the 'B' post to be adjusted so that it is parallel.

It is also most important to check that the door is

completely covering its inner sealing rubber and that

the gap around the door is equal at all heights.

19 When the door position is correct, the lower hinge

can be swung into position and the required hole positions

marked.

20 One of these hole positions can be drilled at 8.5mm,

as before.

21 Remove the three door screws from the upper hinge

before carefully sliding the door open, while continuing

to support the rear edge.

22 With the door open, the top runner can be removed,

followed by removing the two fixing bolts from the

lower runner. The door can then be lifted from the

bottom runner and taken away for its modifications.

Door modifications

1

Remove all of the original lock, handles and linkages. 1

Remove all of the original lock, handles and linkages.

2 If you intend to remove the original external door

release, its entire pressing can be removed from the

door skin by drilling through the eight spot welds.

3 With the pressed recess edges trimmed away, a flat

1mm steel patch may be fitted inside the door skin,

secured with countersunk head pop rivets.

4 Mark out the intended cutting lines to accept the

new lock unit. I was using an Eberhard #1-400-L passenger

restraint lock.

5 With the door laid on a padded support, so that it

is horizontal with the inside facing up. Make two cuts

down the 45° face of the door edge, above and below

the original lock location.

6 Cut along the lower edge of the original lock location,

nearest to the door flange, see diagram #.

7 Cut along the original lock location through the

two outermost lock fixing holes. This will reduce the

length of the 45° tab to allow it to be bent to 90°.

8 Fabricate the reinforcement bracket as diagram #

, and the outer cover piece, diagram #.

9 Insert the reinforcing bracket inside the door and

ensure that it fits snugly in place.

10 Mark the required fixing locations for the new lock.

11 Drill through the tab and the reinforcement for

the lock fixing screws.

12 Remove the reinforcement and apply Sikaflex Auto

inside the door where the reinforcement will go, then

insert it into its position and draw it fully into

place, using spare bolts and nuts.

13 Once the Sikaflex is fully cured (24 hours minimum),

the bolts may be removed.

14 The lock fixing screw holes can be enlarged to allow

the installation of long rivnuts.

15 Apply Sikaflex to the outer cover piece, which is

then held in place by the fitment of the 3 rivnuts.

These pull together the outer cover with the tab and

reinforcement and provide a secure mounting for the

lock. Allow 24 hours for the Sikaflex to fully cure

before continuing.

16 The Eberhard lock required a slot to be cut to allow

its operating lever to be accessed from the inside

the door.

17 The chosen Eberhard door handle also required an

installation hole which was cut through both the door

skin and the reinforcement.

18 Making and installing the linkage rods is not easy

due to the confined space and limited visibility. As

there will be some paintwork to be done after all these

modifications are complete, don't lock linkage rods

in place until you are sure they will not have to be

removed again.

19 If you are not using the original inner door release,

you may need to fabricate a mounting to suit your chosen

handle. I used the original release but added an extension

piece to make it easier to operate.

20 The hole in the inner skin where the lower runner

used to fit passes across the rubber door seal and

may now be patched, if desired.

21 On a trial fit of my door, with new pinchweld seal

rubber installed to the step, I found that the lower

inside panel of the door was bowed, allowing a gap

of some 6mm between the centre of the door and the

seal. To overcome this I cut the grill from the lower

inside panel of the door. I then inserted some wooden

packers inside the door to bring the inner panel straight.

These were then coated in resin to waterproof them

and bond them permanently in place.

22 In order to create a ventilation path that would

comply with the gas requirements, I then cut a series

of 32mm diameter holes below the seal line. Both these

and the previous grill hole will need to be covered

with suitable mesh.

23 Rods and linkages will also need to be fitted to

operate the lock from the inside. I fabricated a bell-crank

assembly to enable me to use the original lock button

in its original position.

24 The area around the patched middle runner port and

the lock position will now need some filler to bring

them to a finished level.

25 If you have removed the original external release

and patched the hole, a thin coat of body filler can

be applied to bring the patched area up to the original

panel level.

26 The door is now ready to be prepared and painted

as required.

Refitting the Door

1

To refit the door, one assistant will be required,

two would be useful. Using a jack or similar to support

the weight of the door, one assistant can hold the

door upright in the open position (90°) while the stainless

steel screws can then be pushed through the hinge tab

and door and have the nyloc nuts fitted on the inside. 1

To refit the door, one assistant will be required,

two would be useful. Using a jack or similar to support

the weight of the door, one assistant can hold the

door upright in the open position (90°) while the stainless

steel screws can then be pushed through the hinge tab

and door and have the nyloc nuts fitted on the inside.

2 Until all six screws are fitted, only lightly tighten

them. The door operation can now be checked to ensure

that it swings smoothly into the correct position.

3 Once the alignment is confirmed, all six screws should

be fully tightened. Lock Striker Pin Since the new

lock has been installed at the same height as the original,

it will be necessary to remove the original pin and

its mounting, to be able to install the new pin, aligned

at 90° to the lock mounting face. To do this the original

pressed pin mount must be removed.

1 Mark the cutting lines around the original pin mount.

2 Using a multi-tool / angle grinder/ chisels etc,

carefully cut around the raised portion and remove

it entirely.